Does any of the following sound familiar to you?

Boiler tubes failed due to corrosion?

Steam generator coil failed due to corrosion?

Boiler or Steam Generator scaled/hotspot failure?

Feedwater pump seals failed/split?

Tube thinning leading to rupture?

Hotwell leaking?

Blocked or failed steam traps?

Steam header or condensate system leaking?

Blocked pipework and plant?

Loss of system efficiency?

Not enough available steam out to process?

Dirty loads or product taint/contamination?

Product “spotting”?

Paying unexpectedly for a hire boiler?

If they do…

It’s very likely then, that you have been unfortunate enough to have experienced poor water treatment and control, leading to poor waterside conditions and subsequently (very expensive) equipment failure and loss of production.

It’s also very likely that before you’ve experienced this unfortunate equipment failure, that your running costs have risen and your system efficiencies have dropped off.

This will have increased your normal running cost considerably.

Eventually you will suffer unplanned breakdowns/shutdowns that will be costing you significant amounts of money in both downtime and lost production.

So… let’s be absolutely clear

It’s comparatively rare for a steam boiler or generator to suffer a failure due to a manufacturing defect or similar.

However…

It is a well-known fact that in excess of 90% of all boiler failures are water treatment related and not mechanically related.

To be clear here, in order for a boiler or steam generator to undergo a water treatment related failure, the existing water treatment control program cannot have been suitable and sufficient to arrest all known failure mechanisms.

Hence water treatment and its control and interpretation is the single most important thing that you need to get right, when running any steam system.

The bottom line is…

If your water treatment application and control is not correct your boiler or steam generator will definitely fail at some point.

On the way to failure, it will have cost you a lot more to run your system.

There is also a requirement to log your test data/training records and service/inspection records.

vSteam®-The state of the art web based monitoring system for steam.

At Deep Water Blue Limited we don’t sell boilers, we don’t sell valves and we don’t sell boiler ancillaries.

We do sell high quality technical water treatment for steam systems.

Contact Mick Casey – 0870 460 2980.

Examples of failure mechanisms;

Pitting Corrosion Attack Due to Oxygen

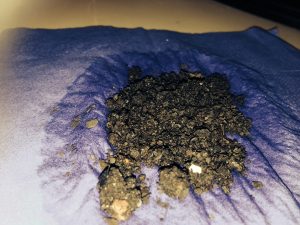

Pipe Blockage due to Precipitation and Deposition

Scale Formation

©Deep Water Blue Limited – all rights reserved.

By Mick Casey – Deep Water Blue Limited

Chartered Chemist/Chartered Scientist

Fellow of The Royal Society of Chemistry

Deep Water Blue Limited

Business & Technology Centre

Bessemer Drive, Stevenage

Herts SG1 2DX

http://www.deepwaterblue.co.uk/

Tel: 0870 460 2980

Fax: 0870 460 2988

Email: info@deepwaterblue.co.uk